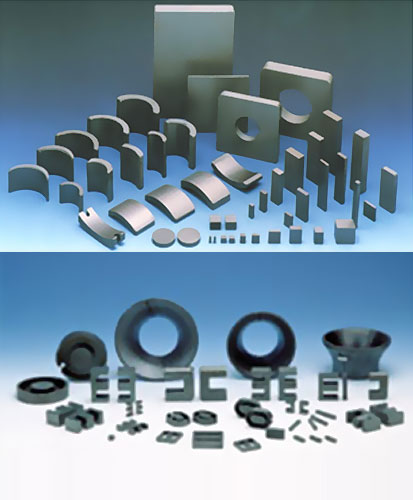

MAGNET

제품소개

(주)에스제이정밀의 마그넷 사업부를 안내합니다.

Raw Material

inspection made to Br, Hcb, Hcj

Mill Material

Reduce size from 0.8~0.9㎛

Press

Polarisation is made

Sintering

1200℃ for 32hours electric sintering ovens

Grinding

Radius, Length, Width, Chamfer

Cleaning & Inspection

Ultrasonic & Visual

Final Inspection & Package

Shipping & Stock

The elements are ferrite oxide, barium, strontium. It is widely used in applications such as motors, loudspeakers and craft etc width low cost.

| Grade | Br | Hcb | Hcj | BHmax | ||||

|---|---|---|---|---|---|---|---|---|

| kG | mT | kOe | KA/m | kOe | KA/m | MGOe | KJ/m3 | |

| Y8T | 2.0~2.35 | 200∼235 | 1.57~2.01 | 125∼160 | 2.64~3.52 | 210∼280 | 0.82~1.19 | 6.5∼9.5 |

| Y22H | 3.1~3.6 | 310∼360 | 2.76~3.14 | 220∼250 | 3.52~4.02 | 280∼320 | 2.51~3.02 | 20.0∼24.0 |

| Y25 | 3.6~4.0 | 360∼400 | 1.70~2.14 | 135∼170 | 1.76~2.51 | 140∼200 | 2.83~3.52 | 22.5∼28.0 |

| Y26H-1 | 3.6~3.9 | 360∼390 | 2.51~3.14 | 200∼250 | 2.83~3.20 | 225∼255 | 2.89~3.52 | 23.0∼28.0 |

| Y26H-2 | 3.6~3.8 | 360∼380 | 3.30~3.62 | 263∼288 | 3.99~4.40 | 318∼350 | 3.02~3.52 | 24.0∼28.0 |

| Y27H | 3.6~3.8 | 350∼380 | 2.83~3.01 | 225∼240 | 2.95~3.27 | 235∼260 | 3.14~3.64 | 25.0∼29.0 |

| Y28 | 3.7~4.0 | 370∼400 | 2.20~2.64 | 175∼210 | 2.26~2.76 | 180∼220 | 3.27~3.77 | 26.0∼30.0 |

| Y28H-1 | 3.8~4.0 | 380∼400 | 3.01~3.27 | 240∼260 | 3.14~3.52 | 250∼280 | 3.39~3.77 | 27.0∼30.0 |

| Y28H-2 | 3.6~3.8 | 360∼380 | 3.40~3.71 | 271∼295 | 4.80~5.09 | 382∼405 | 3.27~3.77 | 26.0∼30.0 |

| Y30H-1 | 3.8~4.0 | 380∼400 | 2.89~3.45 | 230∼275 | 2.95~3.64 | 235∼290 | 3.39~4.02 | 27.0∼32.0 |

| Y30H-2 | 3.95~4.15 | 395∼415 | 3.45~3.77 | 275∼300 | 3.89~4.21 | 310∼335 | 3.39~4.08 | 27.0∼32.5 |

| Y32 | 4.0~4.2 | 400∼420 | 2.01~2.39 | 160∼190 | 2.07~2.45 | 165∼195 | 3.77~4.21 | 30.0∼33.5 |

| Y32H-1 | 4.0~4.2 | 400∼420 | 2.39~2.89 | 190∼230 | 2.89~3.14 | 230∼250 | 3.96~4.40 | 31.5∼35.0 |

| Y32H-2 | 4.0~4.4 | 400∼440 | 2.81~3.01 | 224∼240 | 2.89~3.14 | 230∼250 | 3.90~4.27 | 31.0∼34.0 |

| Y33 | 4.1~4.3 | 410∼430 | 2.76~3.14 | 220∼250 | 2.83~3.20 | 225∼255 | 3.96~4.40 | 31.5∼35.0 |

| Y33H | 4.1~4.3 | 410∼430 | 3.14~3.39 | 250∼270 | 3.14~3.45 | 250∼275 | 3.96~4.40 | 31.5∼35.0 |